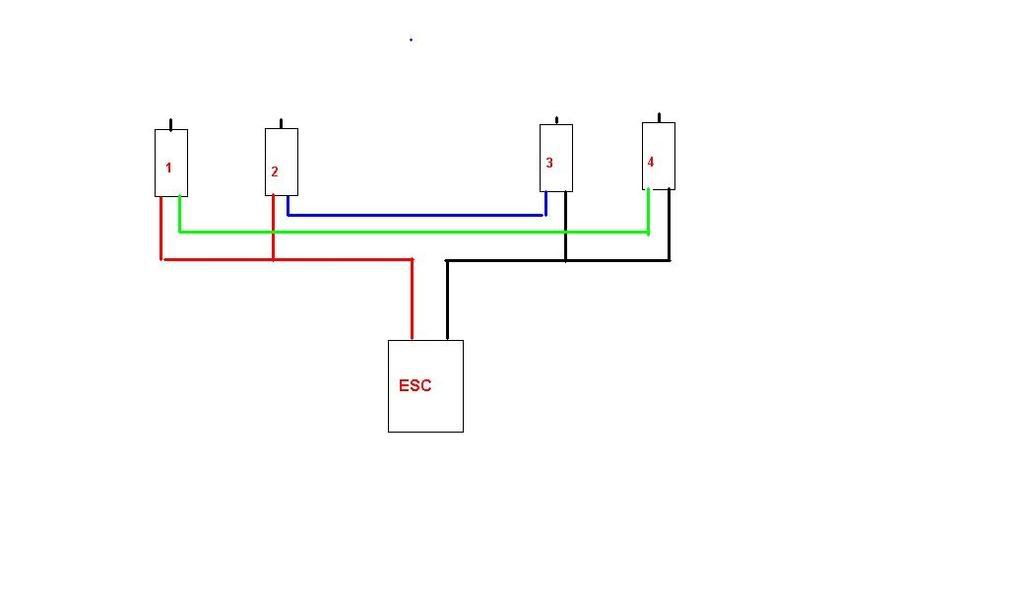

Beberapa catatan, yang mencoba satu esc dan 2 motor BL paralel

http://www.rcgroups.com/forums/showpost ... ostcount=2

Oct 02, 2001, You can use one sensorless controller, wiring the motors in parallel. You may get the occasional false start of one or both motors so it's safer to keep them ticking over in flight rather than stopping them completely.

… “bisa†dilakukan dengan beberapa kemungkinan gagal start di motor, namun solusinya ada, usahakan jangan pernah menurunkan throtle tuk stop motor selagi di udara, (seting trim up bisa dilakukan pada beberapa tx; futaba, optic6 hanya trim down, setelah inisial esc), namun masalah lagi apabila cut off esc-nya (baik karena temperatur atau overload)

http://www.rcgroups.com/forums/showpost ... ostcount=9

Oct 02, 2001, Sean at Aero-Model and myself just completed some testing with twin Hacker brushless motors and a single Jeti sensorless controller using a Graupner Star Jet (on the last cover of Hobby Lobby catalog) as the test bed. We found that after start up we only had false starts if you had the brake enabled when you went to throttle off position. If we left the brake disabled we could start and stop repeatedly without a single glitch. After start up initialization, if one prop gets bumped out of phase with the other, the controller will not be able to start either motor. We completed many flights over several days with this power system and while it really overpowered the airframe from its original speed 400 package, it did prove that a twin motor, single sensorless controller package is workable with a few precautions.

… “bisa†dilakukan pada esc Jeti dan motor Hacker (hi3x, barang mahal nih), dengan seting “brake offâ€. Kenapa terkait dengan merek/pabrik motor serta esc-nya? Akan dijelaskan berikutnya.

Brake off – terkait dengan kondisi throtle off, dimana phase motor berbeda dan mengakibatkan tidak dapatnya tuk start motor kembali.

http://www.rcgroups.com/forums/showpost ... ostcount=6,

Nov 03, 2001, One trick to get both motors to run off of one ESC is to make sure that the 3 wires from the motors are exactly the same length on both motors. Keep the length of these wires to a minimum (I use 8").

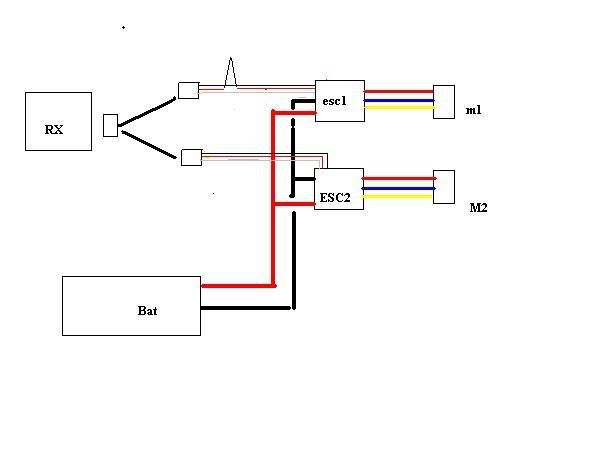

If you use Jeti ESC's it is almost cheaper to just use 2 Jeti's than one Kontronik but you have to live with the additional weight and space they take up. I have a Learjet that runs 2 Jeti 40 3p Opto ESC's running 2 Astro 805s. I prefer to keep the two systems seperate if the application can handle it.

… “bisa†dilakukan pada esc Jeti (lagi) dan motor Astro, dan bisa juga pake esc Kontronik (hi3x, malah lebih mahal lagi). Trik-nya (dengan asumsi esc jeti, motor selain hacker) adalah “pastikan 3 kabel ke motor SAMA PANJANG pada kedua motorâ€. Dan tuk perkabelan (baik motor ataupun batere; riset terpisah, juga biasanya maksimal 8 inci = 20 cm)

http://www.rcgroups.com/forums/showpost ... ostcount=2

Sep 16, 2005, It's been done. The key is to keep the lengths of wire to each of the BL motors the same. Even then, its not guaranteed that both motors will spin up every time.

… “bisa†dilakukan dengan catatan sama seperti diatas, “pastikan 3 kabel ke motor SAMA PANJANG pada kedua motorâ€

http://www.rcgroups.com/forums/showpost ... ostcount=6

Jan 27, 2007, I have a twin EDF50 Feigao 5300kv setup that runs on a single CC25. Best starting single ESC twin motor setup I have yet. I did have to change the timing setting to get it to run. CC keeps changing the software revs, so what works for one guy may not work for another. In that case, you would have to determine the rev to use, and use the PM link to download it into your ESC.

I have an EDF55 twin with Himax 2015-4100 motors that does fairly well on a CC25. I think it is really over pushing the ESC, since there is no room for derating with a 25A rated ESC. I did work well, But sometimes needed a few trys to get started. ONLY ADVANCE THE THROTTLE FOR A SPLIT SECOND, IF NO START, DROP IMMEDIATELY AND TRY AGIAN, or you will burn up. This would be a useable setup on a plane like Stacker's, with EDF55 fans in new nacelles. May work for the EDF64 fans, but I wouldn't go over 220W. Seeing the brushed videos, 220W would fly the plane fine. I changed the plane that had this single ESC into a twin ESC setup now, but the single 25A ESC did fine.

Also, you may want to use the throttle trim to set an idle. That way you will avoid a mid-air shutdown of a motor, if you accidentally drop the throttle to zero.

… “bisaâ€, pada motor Feigao dan himax, dengan esc CC25 (Phoenix Castle Creation, mahal lagi nih, he3x).

Kembali diingatkan agar tidak mematikan motor di udara, dengan seting trim idle throttle.

Beberapa catatan, terkait dengan signal motor BL – 3 phase, yang sering gagal start apabila di paralel

http://www.rcgroups.com/forums/showpost ... ostcount=6

Sep 16, 2005, Brushless motors used on model airplanes are like 3-phase motors used on industry, but are sensorless.

This means the BL ESC set one wire to battery positive, one wire to battery negative, and get the feedback to know when to change to the next phase from the other wire.

When you use 2 motors on the same ESC, the two wires with energy will work ok, but the third wire will have different signals from each motor, because that is impossible to make then to work at the exact same position all the time.

It can work for a few moments and ever takeoff if you're lucky, but when you do a turn one motor will be faster then other, giving erratic signals to ESC and making it halt...

The only way to use 2 BL motors on one ESC is to link both shafts together with the stators and magnets from the bell precisely aligned.

So, to make your model you have two options:

1) Use brushed motors on one ESC (their brushes switch phases)

2) Use two ESCs

Terkait dengan pabrik/merek motor yang berbeda, berbeda pula signal yang dikeluarkan motor (phase 3 dari motor BL), sehingga penggunaan satu esc dapat mengakibatkan bedanya signal yang dikirim oleh motor yang diparalel sehingga gagal start. Kembali terdapat catatan terhadap asymetrical thrust/asynchronous.

http://www.rcgroups.com/forums/showpost ... stcount=19

Sep 17, 2005, A sensorless brushless motor works by apply current to two of the wires, and measuring the voltage generated in the third. It then switches to the next, in essense electronic commutation, replacing the brushes and comm of a brushed motor.

In order to time this switching, you need to measure the voltage in the third wire. In a brushed setup the timing is provided for you because the commutator is mechanically linked to the armature. When you attempt to connect two brushless motors to the same controller there exists the POTENTIAL for the motors to be at unequal places in time. This can be because of but not limited to, differences in construction, loading, individual prop used, wear in the bearings, etc etc etc. There are many factors here, too numerous to list. If this happens the voltage from one can be different enough than the voltage of the other, giving the controller different feedback than it should see. It then cannot apply the right voltage at the right time.

Perhaps this is not all that bad, depending on how hard you are pushing the motor. Perhaps the individual motors are "close enough" for none of it not to matter. Perhaps it is a major problem though and you won't find out till you're in the air. What is the model worth to you? Is it worth trying a couple of the new Thunderbirds 18's instead of the single Ph25? Maybe it might work the other way, but it certainly is not the best way.

There is a lot of information on the net about how brushless motors work, and how they function with sensorless controllers, as other posters have said, it's good reading. As with everything you have to filter out what you find as important, but if trust in your system is such that you wouldn't trust the no name controllers, I don't see any more trust to be placed in a system that isn't set up the way it's designed to work.